Concrete Crusher Proficiency: A Comprehensive Overview to Usage and Upkeep

Concrete Crusher Proficiency: A Comprehensive Overview to Usage and Upkeep

Blog Article

Concrete Crushers: Transforming Waste Into Belongings Resources

Concrete crushers play a crucial duty in the building and demolition market by changing waste products into valuable resources. What kinds of concrete crushers are offered on the market? Twist up and prepare to discover exactly how concrete crushers are reinventing the method we repurpose and take care of waste products.

The Significance of Concrete Crushers

Concrete crushers play an important function in the building market by efficiently transforming waste concrete into important sources. With the increasing demand for lasting building methods, the value of concrete crushers can not be underestimated. These machines are made to damage down large blocks of concrete right into smaller, convenient items, which can then be used in numerous applications.

One of the key reasons why concrete crushers are crucial is their capability to reduce waste. Building and construction projects commonly produce a substantial quantity of concrete waste, which would typically wind up in land fills. Nonetheless, concrete crushers can process this waste product and turn it right into useful aggregates. These aggregates can be made use of to produce new concrete, as a base material for paths and roads, or as fill for building and construction jobs. By repurposing waste concrete, the demand for extracting and refining virgin materials is lowered, causing a more lasting and eco-friendly construction industry.

Furthermore, concrete crushers additionally contribute to cost savings in the building and construction sector. By recycling waste concrete, firms can minimize the costs connected with disposing of concrete waste in landfills.

How Concrete Crushers Job

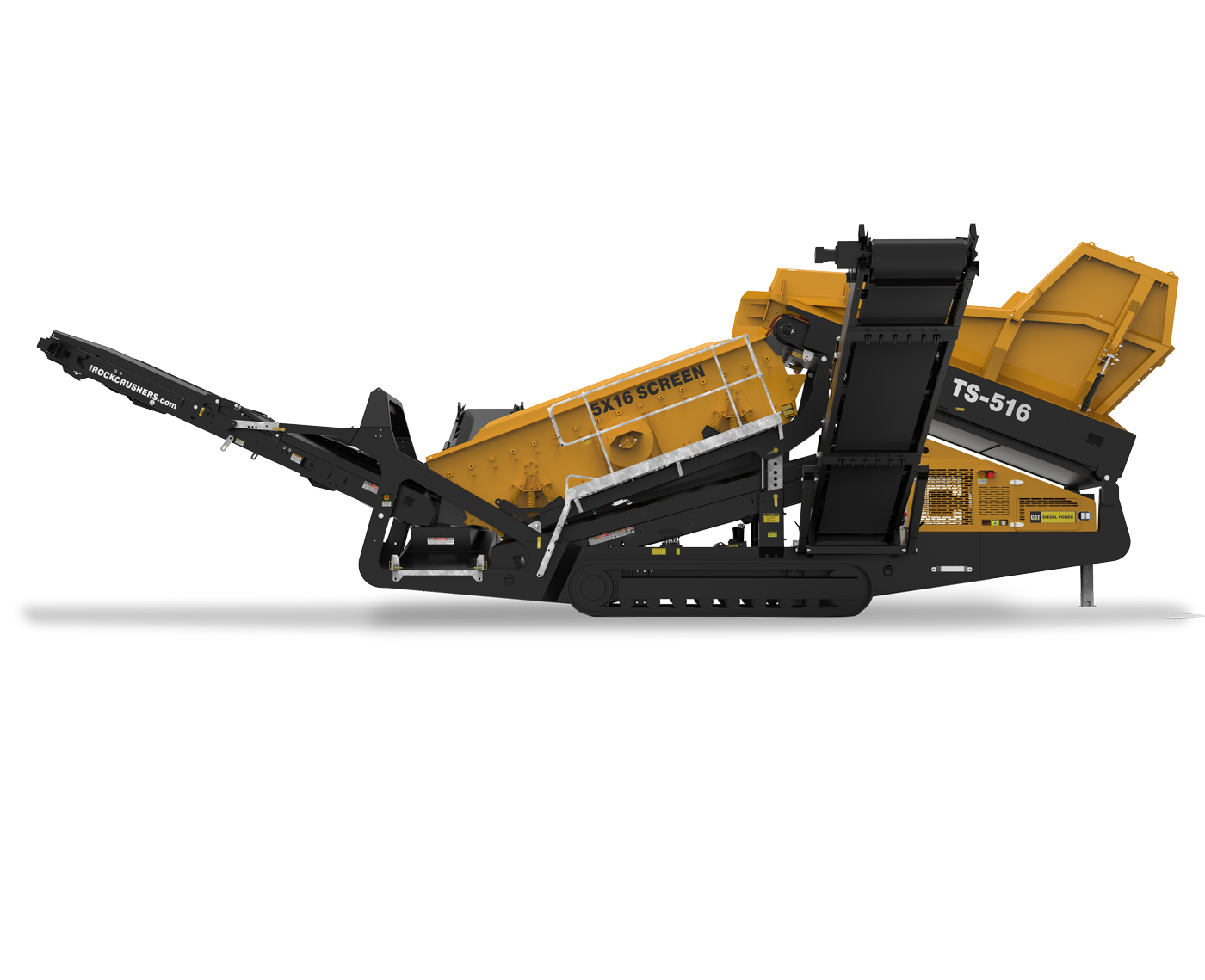

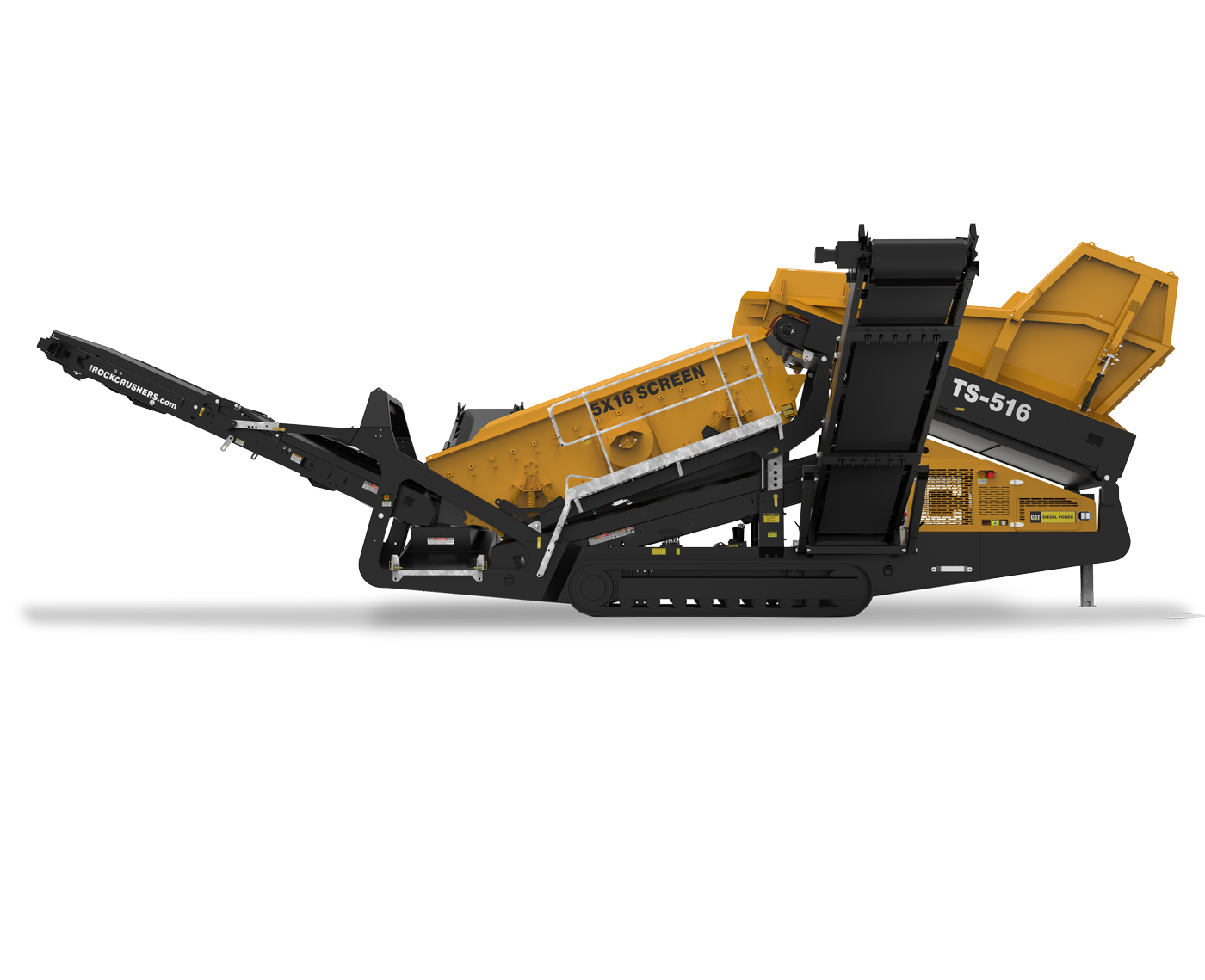

With their capacity to efficiently damage down large blocks of concrete into smaller sized, convenient pieces, concrete crushers demonstrate their crucial duty in the building and construction industry. These makers are specifically developed to decrease the size of concrete waste, making it easier to dispose and transport of. Concrete crushers work by using mechanical force to break concrete right into smaller pieces. They utilize a powerful jaw or impact device that applies stress to the concrete, causing it to disintegrate (concrete crusher). The dimension of the concrete pieces generated can be changed by managing the setups of the crusher, permitting adaptability in the preferred final product.

Concrete crushers been available in different dimensions and types, however they all operate in a comparable fashion. The concrete is fed into the crusher via a receptacle or chute, and it is then crushed between a moving jaw or an effect plate and a fixed plate. The resulting pieces are then discharged with an opening at the end of the crusher. Some crushers might likewise have an additional squashing phase, where the smashed concrete is additional reduced in dimension.

Kinds of Concrete Crushers

What are the different kinds of crushers utilized for damaging down concrete waste in the building sector? There are numerous types of concrete crushers that are frequently used in the building market. These consist of jaw crushers, impact crushers, cone crushers, and hammer crushers.

Jaw crushers are frequently used as primary crushers. They are created to crush large items of concrete into smaller sized bits that can be used for page different construction purposes. Jaw crushers have actually a fixed jaw and a movable jaw that move back and forth to squash the concrete.

Influence crushers, on the other hand, are utilized for second squashing. They are created to crush the concrete into smaller sized particles by applying pressure through impact. Influence crushers can be either straight shaft impactors or vertical shaft impactors.

Cone crushers are used for tertiary crushing. They are made to squash the concrete into even smaller fragments. Cone crushers have a cone-shaped crushing chamber that revolves around its own axis.

Lastly, hammer crushers are used for crushing concrete right into fine particles. They work by using a high-speed effect pressure to the concrete.

Benefits of Concrete Crushing

One of the significant advantages of concrete crushing is the reliable usage of waste resources in the building sector - concrete crusher. Concrete is among one of the most utilized materials in the building market, and because of this, big quantities of concrete waste are created throughout building and construction and demolition tasks. Nevertheless, as opposed to disposing of this waste in land fills, concrete squashing offers an environmentally-friendly and sustainable solution.

By utilizing concrete crushers, the waste concrete can be squashed into smaller items and reused as accumulation in brand-new building and construction projects. This not just aids in decreasing the demand for natural deposits but likewise decreases the ecological influence connected with the extraction and processing of these resources. Furthermore, it helps in conserving landfill room by diverting the waste from land fills.

Additionally, concrete squashing provides useful source economic advantages. Recycling concrete waste decreases the demand for new building products, hence resulting in expense savings for building business. The recycled concrete can be sold to various other construction tasks or utilized for roadway base and landscaping functions, creating extra revenue.

Applications of Recycled Concrete Products

Recycled concrete products locate a broad range of applications in different building tasks, many thanks to their durability and sustainability. One of the common applications of recycled concrete products is as a base or subbase material for pavements and roads. The smashed concrete can be utilized as a secure foundation for new building, lowering the demand for virgin aggregates and conserving natural deposits. Additionally, recycled concrete products can be used as fill material in land improvement projects, supplying a cost-efficient and ecologically friendly option.

One more application of recycled concrete materials is in the production of new concrete. Crushed concrete can be utilized as a substitute for natural accumulations, such see this as crushed rock or crushed rock, in the production of concrete.

Recycled concrete materials can additionally be utilized for erosion control and incline stabilization (concrete crusher). The smashed concrete can be used to develop maintaining wall surfaces, embankments, and other frameworks that prevent dirt erosion and provide security to inclines

Final Thought

Finally, concrete crushers play a crucial function in changing waste into useful resources. By effectively damaging down concrete structures, these devices make it possible for the recycling of concrete materials, minimizing the need for new building and construction materials and lessening ecological effect. With various kinds and advantages, concrete crushers have a variety of applications in the building and construction industry. Accepting using recycled concrete materials can add to sustainable growth and resource conservation.

Report this page